Why to partner with a tool and die maker for complex tooling

Discover the Perks of Utilizing CNC Machining Providers for Precision Design and Manufacturing

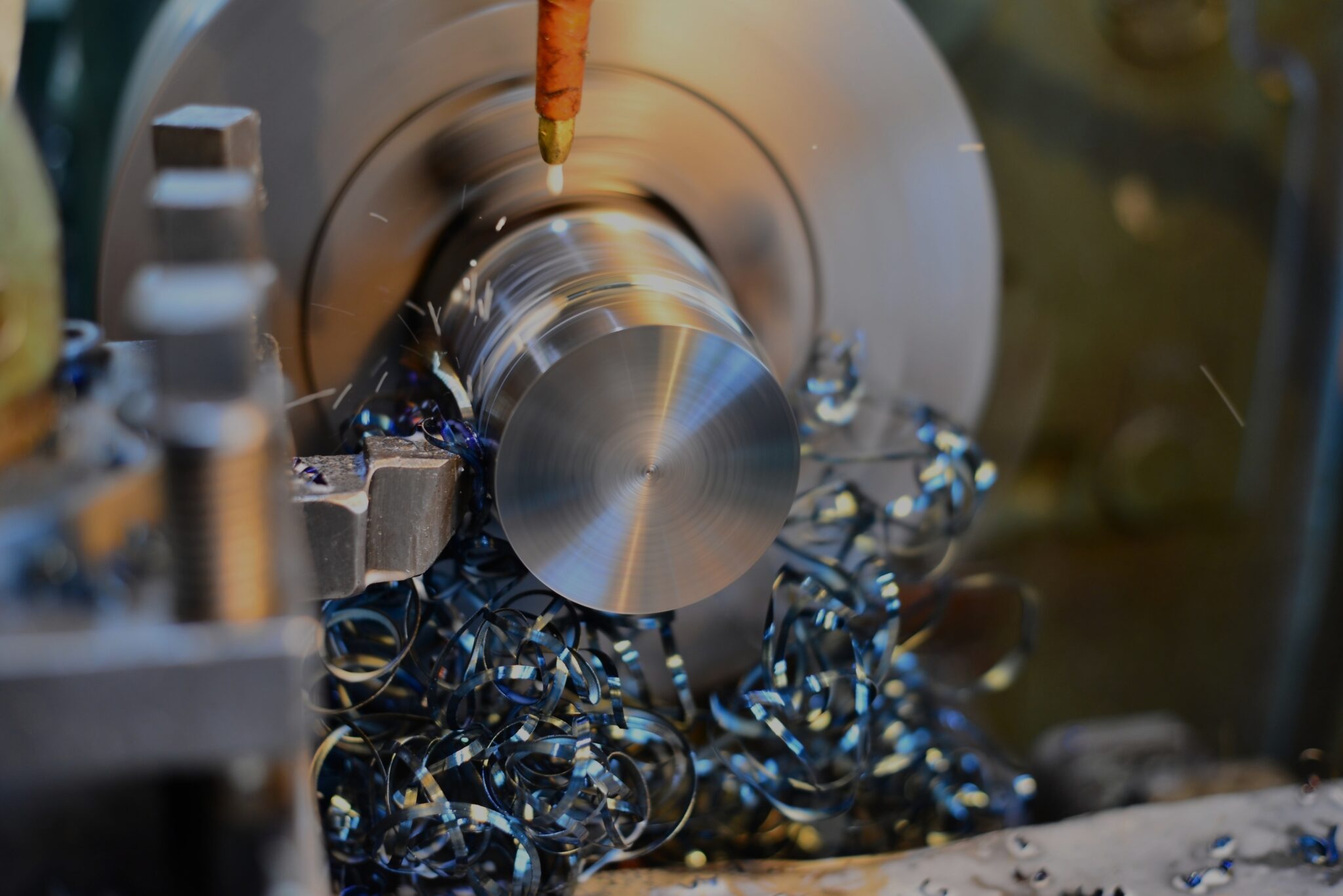

CNC machining solutions supply considerable benefits for precision engineering and production. By using sophisticated computer-controlled equipment, these services ensure high degrees of accuracy and effectiveness. This modern technology allows for the development of detailed elements from various materials, minimizing human mistake and production time. Nonetheless, the benefits expand beyond precision alone, hinting at much deeper effect on productivity and cost-efficiency that are crucial for modern industries. Discovering these elements reveals a more substantial understanding of CNC machining's duty.

Boosted Precision and Accuracy

As sectors significantly require greater criteria, CNC machining solutions have arised as an essential service for achieving enhanced precision and accuracy in engineering applications. These services make use of innovative computer-controlled equipment to generate elaborate components that meet stringent specifications. The capacity to program specific dimensions lessens human mistake, making sure that each part is manufactured to exacting tolerances.

CNC machining is particularly beneficial in sectors such as aerospace, auto, and clinical gadgets, where accuracy is vital. The innovation enables the production of intricate geometries that traditional machining methods might have a hard time to achieve. By using CAD designs, CNC makers can replicate layouts with impressive fidelity, causing consistent high quality across manufacturing runs.

Raised Efficiency and Performance

Moreover, CNC modern technology permits for the synchronised handling of multiple components, resulting in higher production rates. The capability to run makers continually, also throughout non-working hours, maximizes operational time and resource utilization. Additionally, the quick setup and transition times connected with CNC machining promote quick adjustment to various job demands, enabling manufacturers to respond swiftly to market needs.

Cost-efficient Manufacturing Solutions

Moreover, CNC machining enables for quick prototyping and production runs, which helps to enhance the production procedure and decrease lead times. The ability to create complicated geometries with marginal product waste further adds to cost savings. fast prototyping. Because of this, business can designate funds extra successfully and buy other areas of their operations. In general, CNC machining services offer a trusted path published here for businesses to enhance profitability while maintaining high standards in product quality and performance

Flexibility in Material Compatibility

The flexibility of CNC machining services in material compatibility is one of its most significant advantages. This capacity permits suppliers to function with a diverse variety of materials, including plastics, metals, and composites. Each product can be carefully machined to fulfill details design demands, resulting in components that are both top quality and useful. For aluminum, steel and circumstances are generally utilized for their strength and durability, while plastics can be picked for their corrosion-resistant and light-weight residential or commercial properties. CNC devices are outfitted to deal with various material buildings, making sure that the desired specs are met precision. This adaptability not only improves the design possibilities but additionally enables makers to customize their products to different sector needs, from aerospace to medical and vehicle applications. Inevitably, the ability to successfully utilize multiple products simplifies the production procedure and widens the scope of ingenious design remedies.

Streamlined Prototyping and Layout Iteration

Enhancing the prototyping and layout iteration process is a crucial advantage of innovative machining technologies. CNC machining services allow developers and designers to promptly generate precise prototypes, helping with fast screening and examination. This performance substantially reduces the time from concept to production, enabling companies to iterate designs swiftly based on real-world feedback.

CNC machining's high accuracy lessens errors, guaranteeing that each prototype closely mirrors the final item requirements. The capacity to function with different materials further enhances the layout opportunities, permitting thorough testing throughout various situations.

Therefore, services can improve their items better, adapting to market demands and customer choices. This responsiveness is necessary in today's affordable landscape, where advancement and speed are critical. Utilizing CNC machining solutions not only accelerates the growth process but likewise enhances the total high quality and reliability of the last produced goods.

Regularly Asked Concerns

What Industries Advantage A Lot Of From CNC Machining Services?

The aerospace, auto, medical, and electronic devices markets benefit most from CNC machining solutions. These sectors call for high precision, intricate styles, and consistent top quality, making CNC machining necessary for producing intricate parts and meeting stringent industry requirements.

Exactly How Does CNC Machining Contrast to Typical Production Techniques?

CNC machining offers greater flexibility, effectiveness, and accuracy compared to standard production methods. It lessens human mistake, enables complicated layouts, and permits fast prototyping, ultimately resulting in better manufacturing high quality and lowered preparations.

What Kinds Of CNC Machines Are Commonly Used?

What Is the Common Lead Time for CNC Machining Projects?

The normal lead time for CNC machining jobs usually ranges from a few days to a number of weeks, depending on variables like complexity, product availability, job size, and the maker's work, affecting total shipment timelines.

Exist Any Kind Of Limitations to CNC Machining Solutions?

CNC machining solutions do have limitations, including product constraints, complexity of layouts, and dimension restrictions. Furthermore, detailed geometries may need customized tooling, which can enhance manufacturing time and prices, affecting general task feasibility.

CNC machining services use substantial advantages for precision engineering and production - fast prototyping. As markets significantly require higher standards, CNC machining services have actually arised as a vital service for achieving improved accuracy and precision in design applications. CNC machining services not just improve precision yet also considerably boost performance and efficiency in manufacturing procedures. CNC machining offers better versatility, efficiency, and precision More Help compared to conventional manufacturing methods. Typically used CNC devices include CNC lathes, CNC milling equipments, CNC routers, CNC plasma cutters, and CNC laser cutters